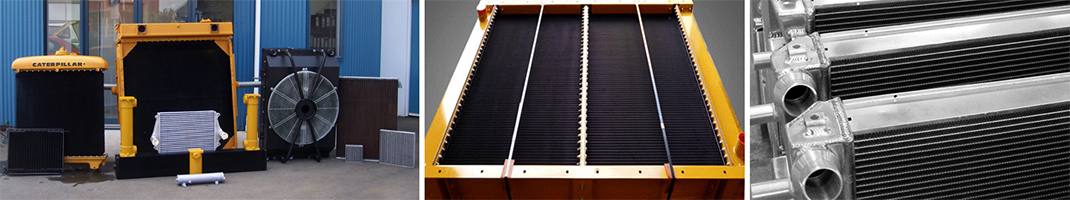

Charge after coolers for mining, trucks and industrial

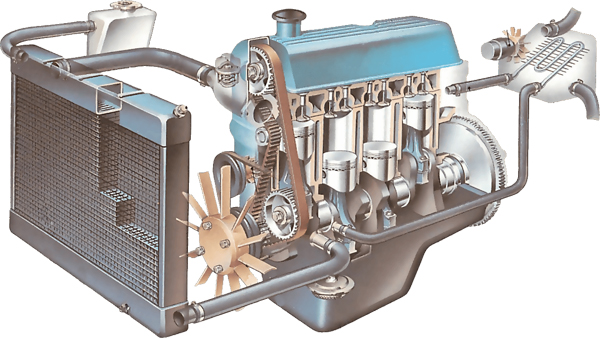

We understands engine cooling applications and offer full design and manufacture of integrated cooling systems. After cooler / air cooler is just one of the essential components of engine and the equipment's cooling system. It cools the air going to your engine, when and after cooler starts to fail, so does your cooling system. It can put serious stress on your engine and equipment's performance too.

Our inter coolers are designed using CFD analysis to ensure smooth flow of air inside the flow channels and headers so that there is minimal pressure drop across the cooler. The coolers are given a special protective coating to prevent corrosion in very harsh operating conditions.

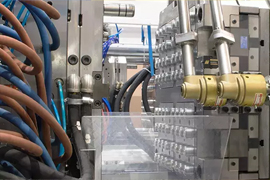

Extended surface heat exchanger

Customized design for centrifugal compressor intercoolers & after coolers. They are capable of cooling large volumes of air or nitrogen at minimal pressure loss, close temperature approach to cooling water is possible. It is a removable bundle design with multi-pass tube side, internal demister mounting for wet air condensation is most compact and energy efficient solution for the gas cooling application.

Pressure vessels

Pressure vessels are most commonly used in almost all industries like refineries, chemical plants and fertilizer plants.

These pressure vessels are mainly used as gas storage, water storage, air receivers, separators, fuel tank and buffer vessels

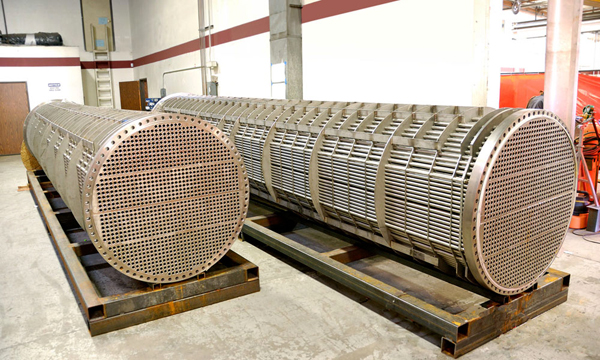

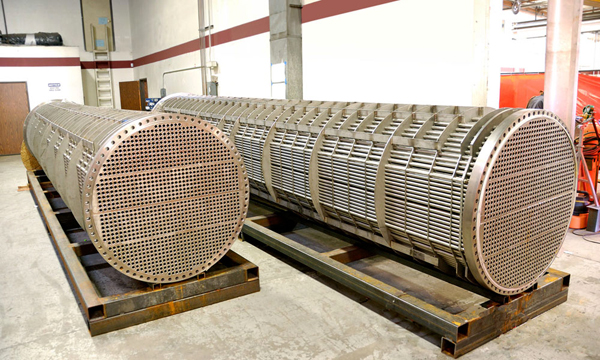

Tube bundle heat exchanger

An intermediate tube bottom, having insert tubes arranged concentrically in the tubes, is located in the inlet chamber, with these insert tubes projecting out on both sides from the tubes and forming annular spaces therewith. The heat exchanger has an inlet tube bottom and an outlet tube bottom, in which are fastened the ends of tubes which connect the bottoms and through which the medium of high inlet temperature flows.

A tube-bundle heat exchanger for cooling a medium having a high inlet temperature. Toward the inlet chamber, the annular spaces open into an intermediate chamber limited by the inlet tube bottom and the intermediate tube bottom; in the opposite direction, the annular spaces open into a deflecting or reversing chamber sealingly covering the insert tubes.

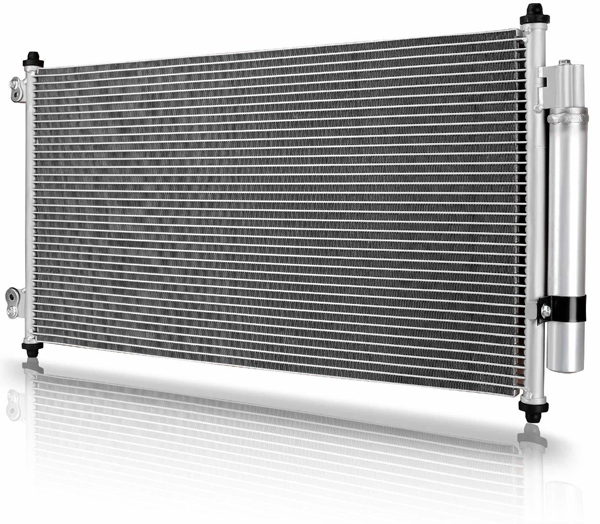

Condensers

Condensers are for mining equipments used in their air conditioner & chillers in many manufacturing industries. It contains gas, water, calcium chloride, oil solvents, tri-chloroethylene.

The condenser is located between the compressor and the expansion valve. Hot, high pressure refrigerant vapor enters the condenser and liquid refrigerant exits the condenser. It perform the best temperature requirement as per various equipment's and industries.

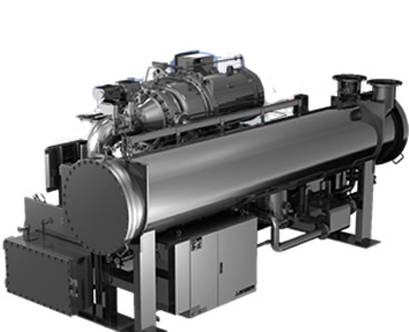

Shell and tube type chillers

The shell and tube type chillers have multi pass covers which are used in both ends to match design gas flow. The tube passes are designed to 4, 6 or 8 passes with single / double circulation. Baffle arrangement is designed to control fluid velocity outside the tubes. Short cut of baffle with wide spacing are used for low pressure drop and full cut-off are used for greater velocity when fluid rate is low.